Unique solutions in Process Analytical Technology

Our Solutions

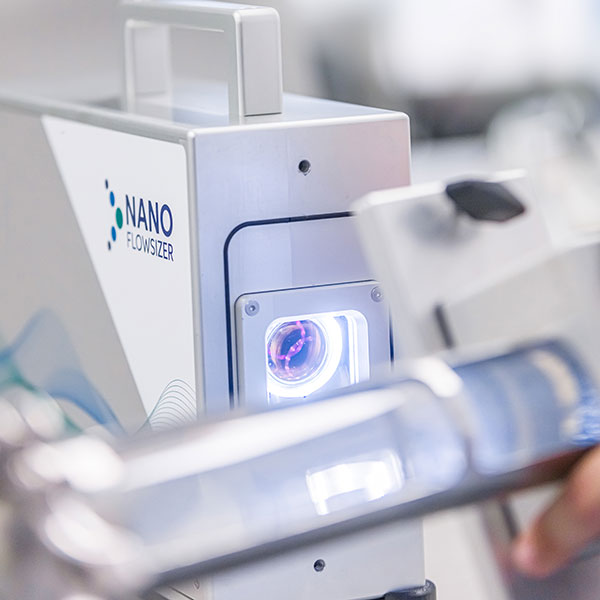

The NanoFlowSizer

Inline & Real-Time Particle Size Characterization

The NanoFlowSizer is a non-invasive, in-line measurement instrument that delivers accurate, real-time particle size data—without dilution or sampling.

- Based on our patented SR-DLS technology

- In-flow, at-line, online & offline measurements

- Ideal for wide sample turbidity ranges

- Real-time feedback in seconds

- Scalable from lab to GMP manufacturing

For truly inline size characterization, the NanoFlowSizer is a powerful Process Analytical Tool.

NEW – The NanoLabSizer

Non-Destructive Offline Particle Size Analysis

Nanoparticle size characterization in transparent containers—no flow, no prep.

Perfect for early formulation, transfection complex monitoring, or sensitive materials.

- Based on our patented SR-DLS core technology

- Real-time monitoring of complex formation

- Measure directly through closed bags, flasks, vials or tubes – no sampling

- Preserve sterility and eliminate handling variability

- Flexible development scale (up to 3 L) – ideal for DoE studies

Real Problems? Real Solutions.

Still dealing with:

- Sampling that breaks sterility?

- Missing early signs of aggregation?

- Still diluting to know particle size?

- Limited control over nanoparticle processes?

Our tools help you move from offline guessing to real-time understanding—without disrupting your process or compromising sample integrity.

Why Our Technology Stands Out

- SR-DLS: A patented breakthrough

> Over 1,000 depth-resolved measurements for full sample insight - Handles turbidity ranges where others fail

- Compatible with sterile and continuous processes

- Real-time data every 5–10 seconds

- GMP-ready and scalable from R&D to manufacturing

Key Application Areas

This small instrument made a huge impact!

Where we add value in your workflow

R&D and Formulation

- Fast screening of formulations

- Real-time insights on aggregation, stability, nucleation

Process Development & Scale-Up

- Optimize emulsification, LNP formation, milling

- Replace manual testing with live process data

Manufacturing & GMP Production

- Monitor CQAs like particle size inline

- Enable real-time release and reduce batch failures

The InProcess-LSP Team

Core strengths

- Specialists in nanoparticle size analysis

- Creators of the NanoFlowSizer technology

- Specialists in continuous manufacturing & PAT integration

- Agile, collaborative and customer-focused

- Strong background in process optimization and product development

The InProcess-LSP solution

Real-Time NanoParticle Analysis

- Reduction in analysis time, results in seconds

- Increased process understanding

- Particle size information in real time

- Reduction of production time

- Potential for significant batch reductions

Where can you meet us?

Dr. R. Besseling presenting on wednesday 4.30 PM.

Meet us at our booth!

Creates significant cost savings for your process

Case Studies & Articles

- How do results from different dynamic light scattering instruments compare?

- How can you improve your PEI-based transient transfection process?

- Monitoring Protein Aggregation During Downstream Processing – Insights Using the NanoFlowSizer

- Lipid-Based Nanoparticles: Manufacturing and inline size Characterization